TopModel (France), under the banner of their ECOTOP brand, now offers the 3.0M Bidule 111 which is about the same size plane as the much beloved 3.2M Pilatus Porter. The Bidule 111 is designed around the DLE 111 twin cylinder gas engine. The DA-100 and DA-120 engines share the exact same size mounting bolt pattern and similar size and weight to the DLE 111.

Our dilemma...we have both a DA-100 and a DA-120 looking for a home...which engine should we chose?

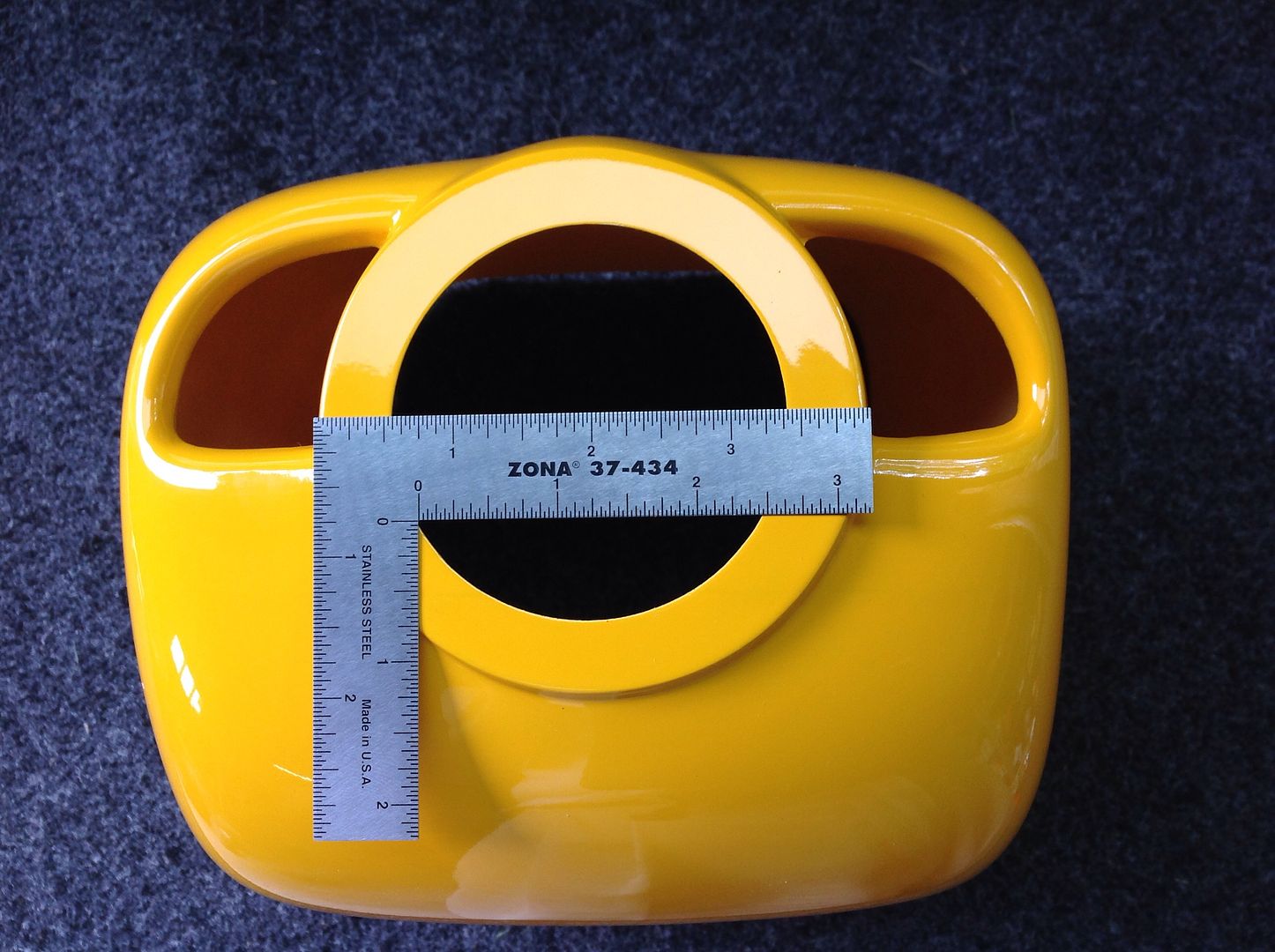

Compared to the Porter, the Bidule 111 (being a non-scale airplane) has a smaller fuselage and less overall mass. Consequently, its AUW will be about 8-10 lbs. less than the Porter. Our Porter is the 3.37M span version so the 3.0M Bidule 111 has about 14-1/2" less span. Also, the included 1500cc (50 oz) fuel tank is a tight fit, so there will not be a 100 oz tank option here...that means the Bidule will be carrying 50 oz. less fuel and less weight in fuel.

So, the Bidule 111 is smaller and lighter weight than the Porter...seems like the DA-100 should be plenty of power for the size and weight of the plane. Then there is the muffler issue. Do we use stock mufflers and save the cost and weight of canisters or tuned pipes? Our reason for this plane is to have a backup tow plane that is less costly than either the Porter or Decathlon, and one that we would not be as reluctant to fly on less than ideal days. So, cost is a factor, and therefore here are our choices:

Bidule 111 Accessories:

Engine: DA-100

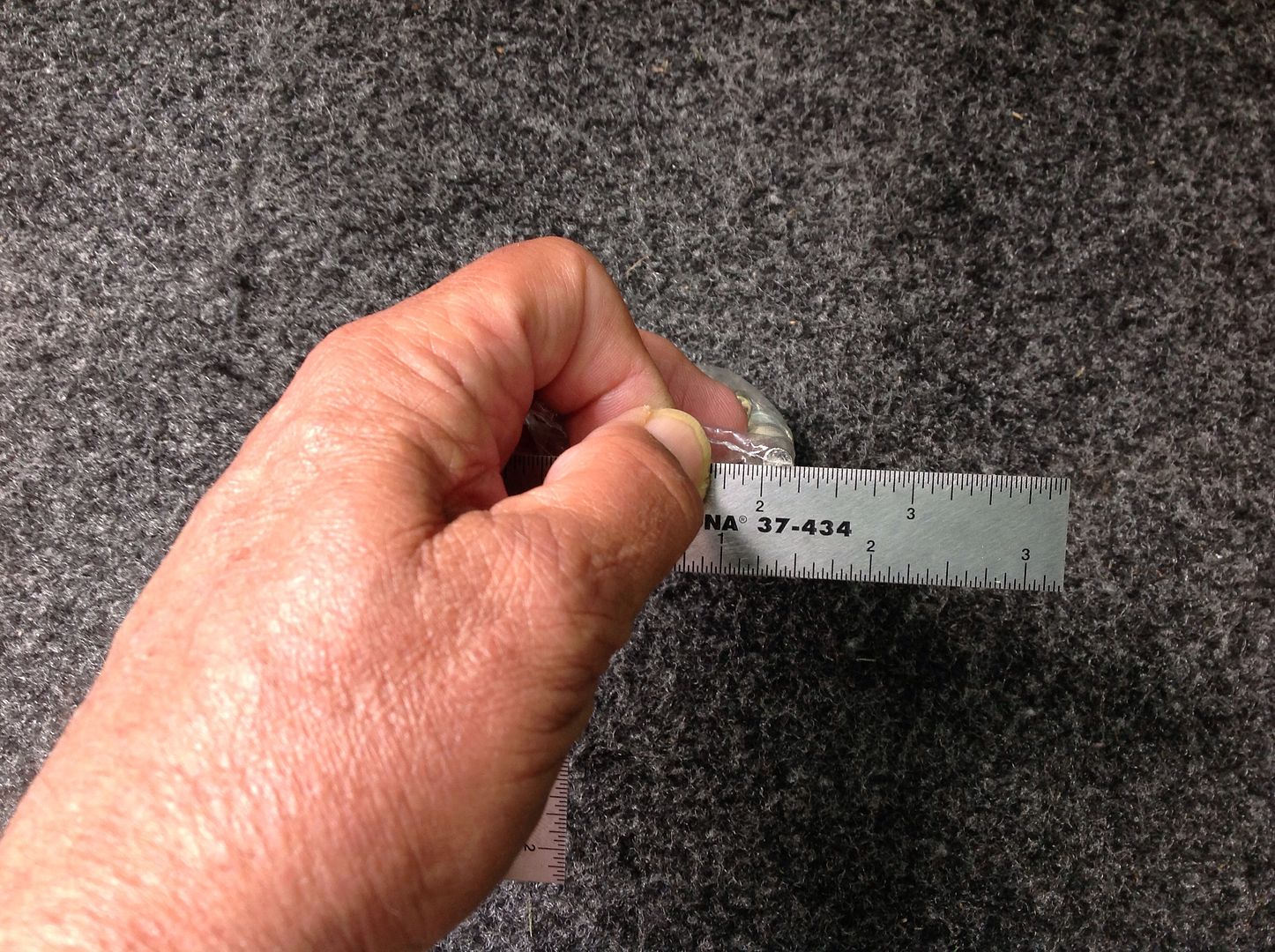

Spinner: 4" Dave Brown Vortech Aluminum Spinner

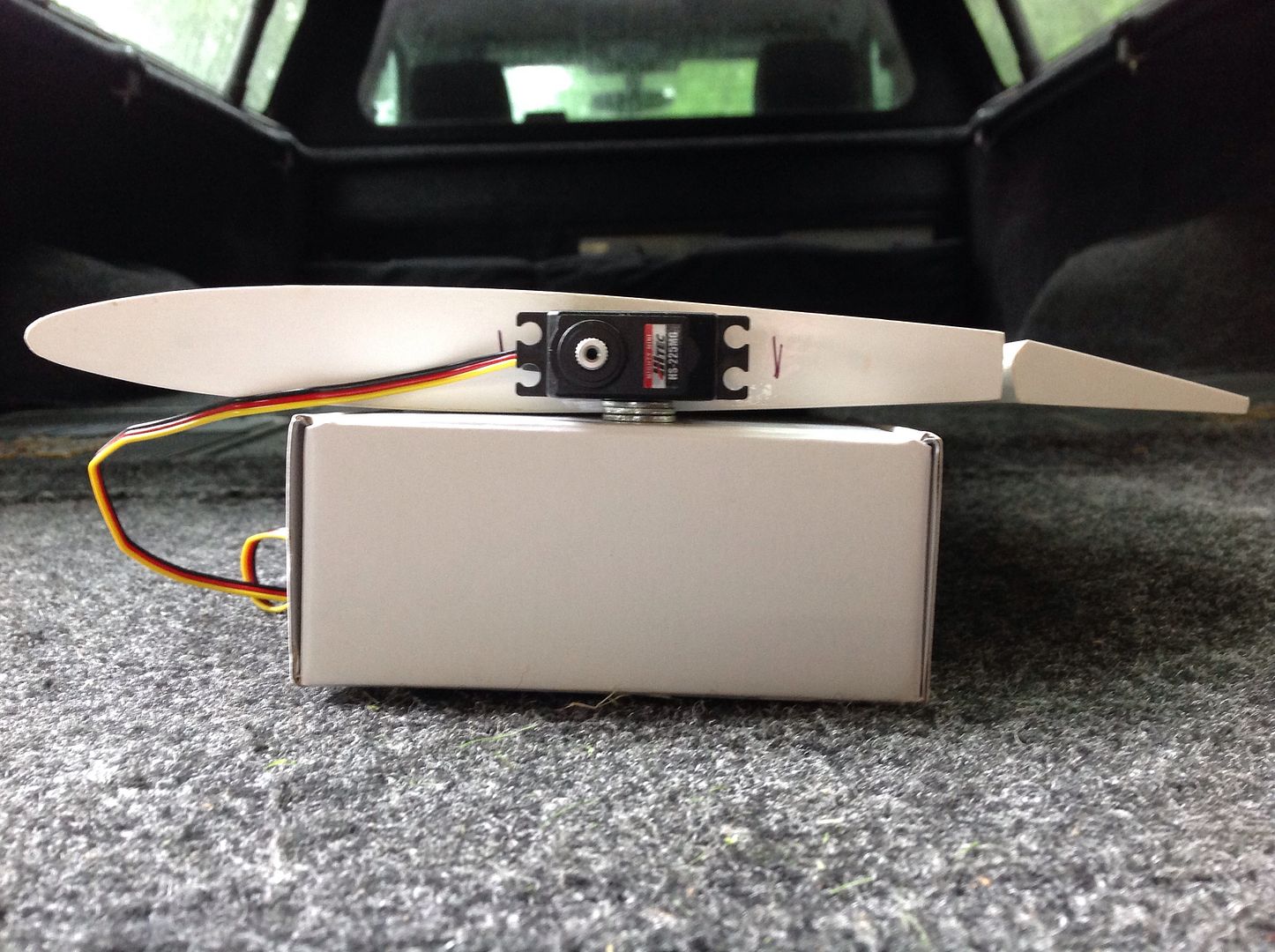

Prop: Xoar 26x12 Wood

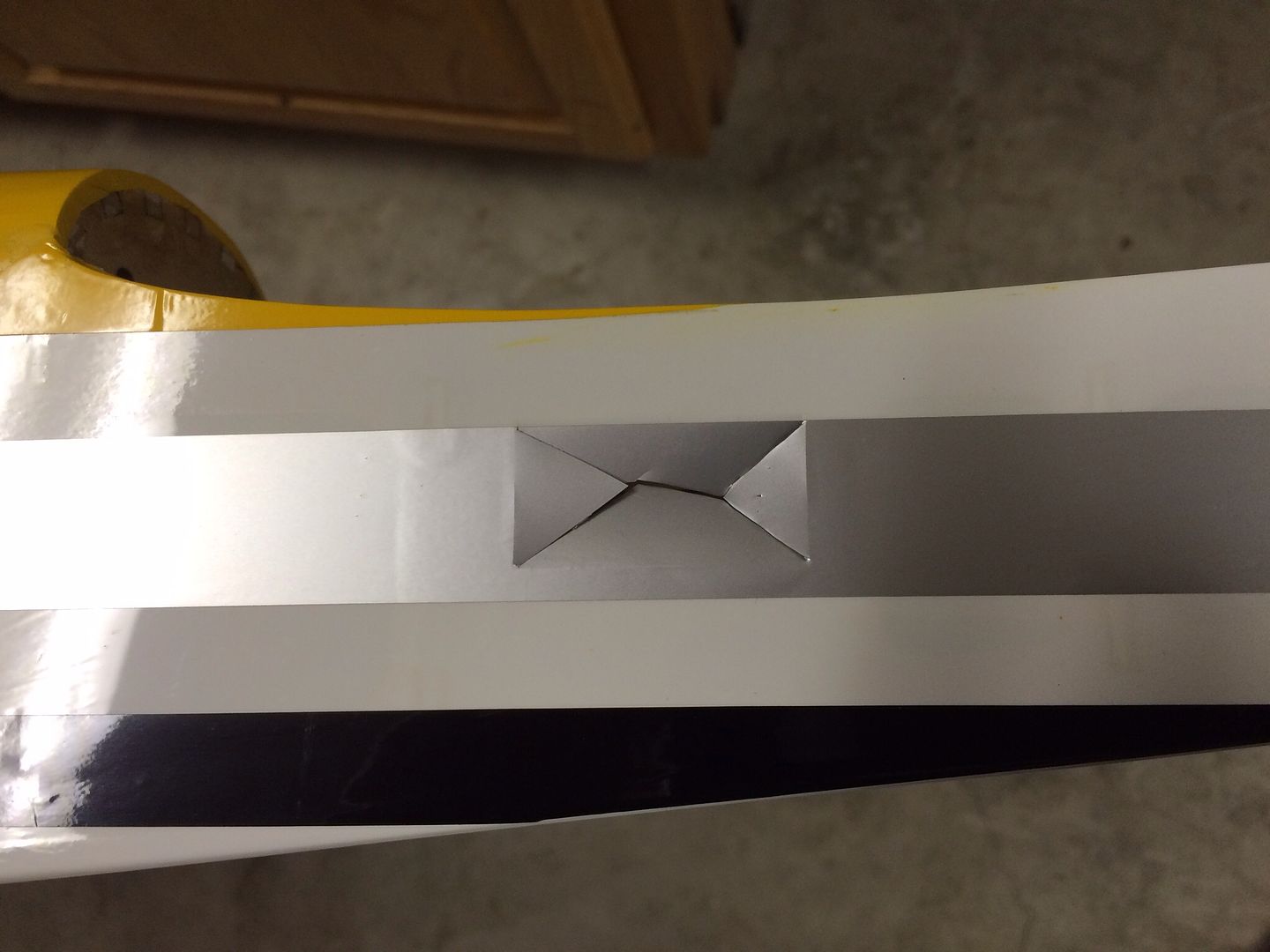

Servos: Hitec HS-5645MG for Ailerons, Elevators, Flaps, Tow Release, Choke, and Throttle. (9 total). Hitec HS-5245MG for rudders (2 total). Hitec HS-7954SH for nose wheel sterring (one total).

Batteries: NoBS Batteries 2-cell 6.6v A123 LiFe 2,500ma packs, 2 for radio gear and 1 for ignition ( three total)

Wheels: DuBro 5" Treaded Lightweight Wheel for nose gear and a pair of DuBro 6" Treaded Lightweight Wheels for the main gear.

Our dilemma...we have both a DA-100 and a DA-120 looking for a home...which engine should we chose?

Compared to the Porter, the Bidule 111 (being a non-scale airplane) has a smaller fuselage and less overall mass. Consequently, its AUW will be about 8-10 lbs. less than the Porter. Our Porter is the 3.37M span version so the 3.0M Bidule 111 has about 14-1/2" less span. Also, the included 1500cc (50 oz) fuel tank is a tight fit, so there will not be a 100 oz tank option here...that means the Bidule will be carrying 50 oz. less fuel and less weight in fuel.

So, the Bidule 111 is smaller and lighter weight than the Porter...seems like the DA-100 should be plenty of power for the size and weight of the plane. Then there is the muffler issue. Do we use stock mufflers and save the cost and weight of canisters or tuned pipes? Our reason for this plane is to have a backup tow plane that is less costly than either the Porter or Decathlon, and one that we would not be as reluctant to fly on less than ideal days. So, cost is a factor, and therefore here are our choices:

Bidule 111 Accessories:

Engine: DA-100

Spinner: 4" Dave Brown Vortech Aluminum Spinner

Prop: Xoar 26x12 Wood

Servos: Hitec HS-5645MG for Ailerons, Elevators, Flaps, Tow Release, Choke, and Throttle. (9 total). Hitec HS-5245MG for rudders (2 total). Hitec HS-7954SH for nose wheel sterring (one total).

Batteries: NoBS Batteries 2-cell 6.6v A123 LiFe 2,500ma packs, 2 for radio gear and 1 for ignition ( three total)

Wheels: DuBro 5" Treaded Lightweight Wheel for nose gear and a pair of DuBro 6" Treaded Lightweight Wheels for the main gear.

Comment