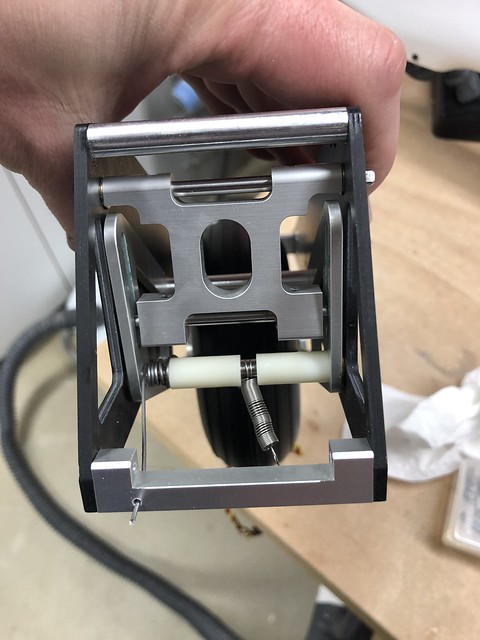

Aluminum attachment plate with 6-32 hardware.

Fits perfect with good clearance all around. Hope it works!

Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr Sans titre by steffruelle, sur Flickr

Sans titre by steffruelle, sur Flickr

Leave a comment: