StephaneR (aka French1) made us aware of the success of the Bidule design in France and that set in motion a group order from TopModel. After Len's Bidule 170 (with ZDZ-180 engine) went into service this summer, it became crystal clear that this model is the current segment defining aircraft for aerotowing. We really need to thank BobM for putting together the group buy through ICare that brought the first of these planes into the USA. Then we need to thank ScotS (Stew) for actually transporting them from Etienne's shop in Canada to us here in the states, and of course Stephane for the idea in the first place!

Bob has already posted extensive pictures of his build and modifications, but I am taking a little different path than either he or Len. This plane will no doubt be the subject of numerous build threads and every builder has their own ideas. This will be my take on the subject.

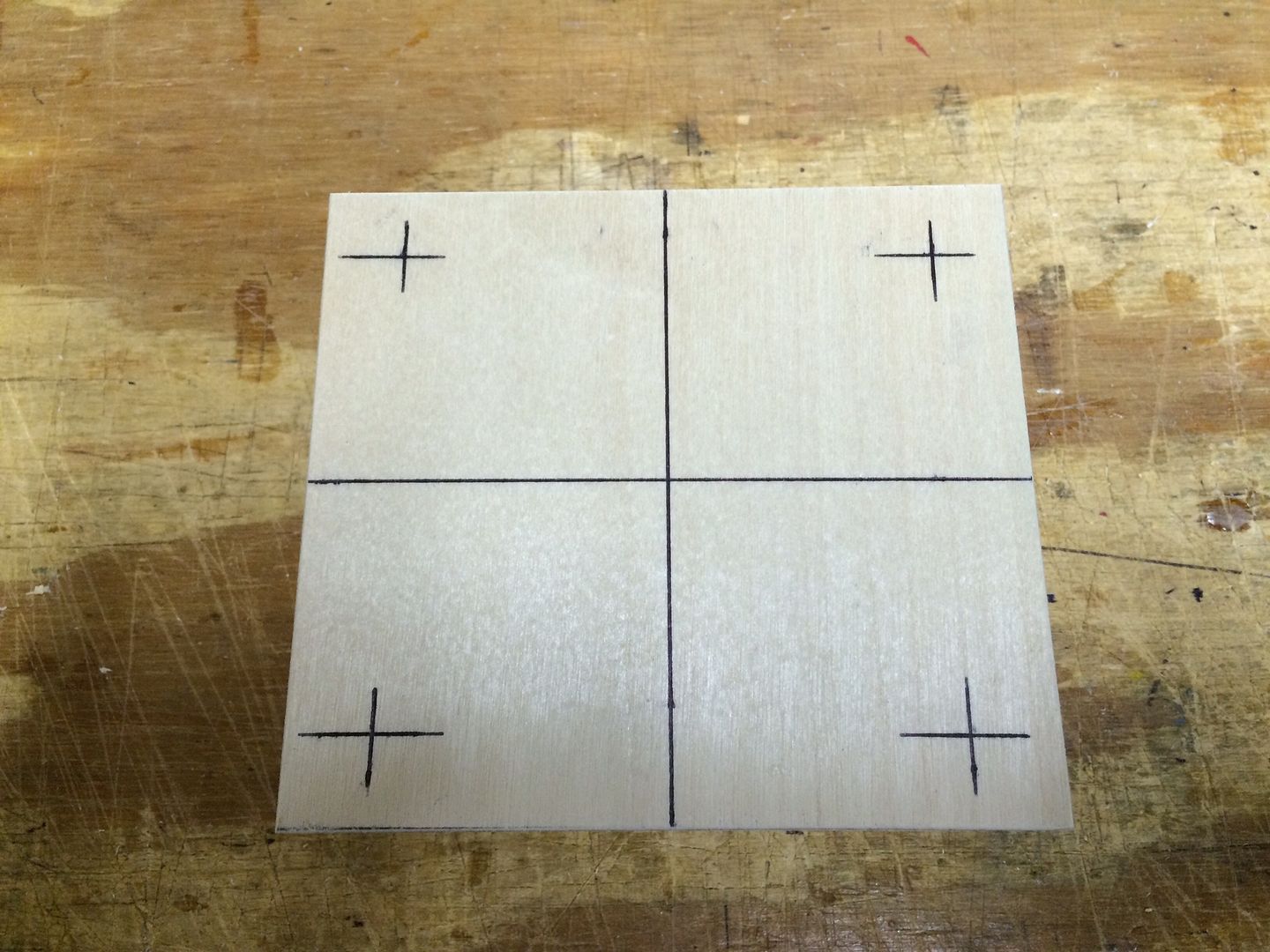

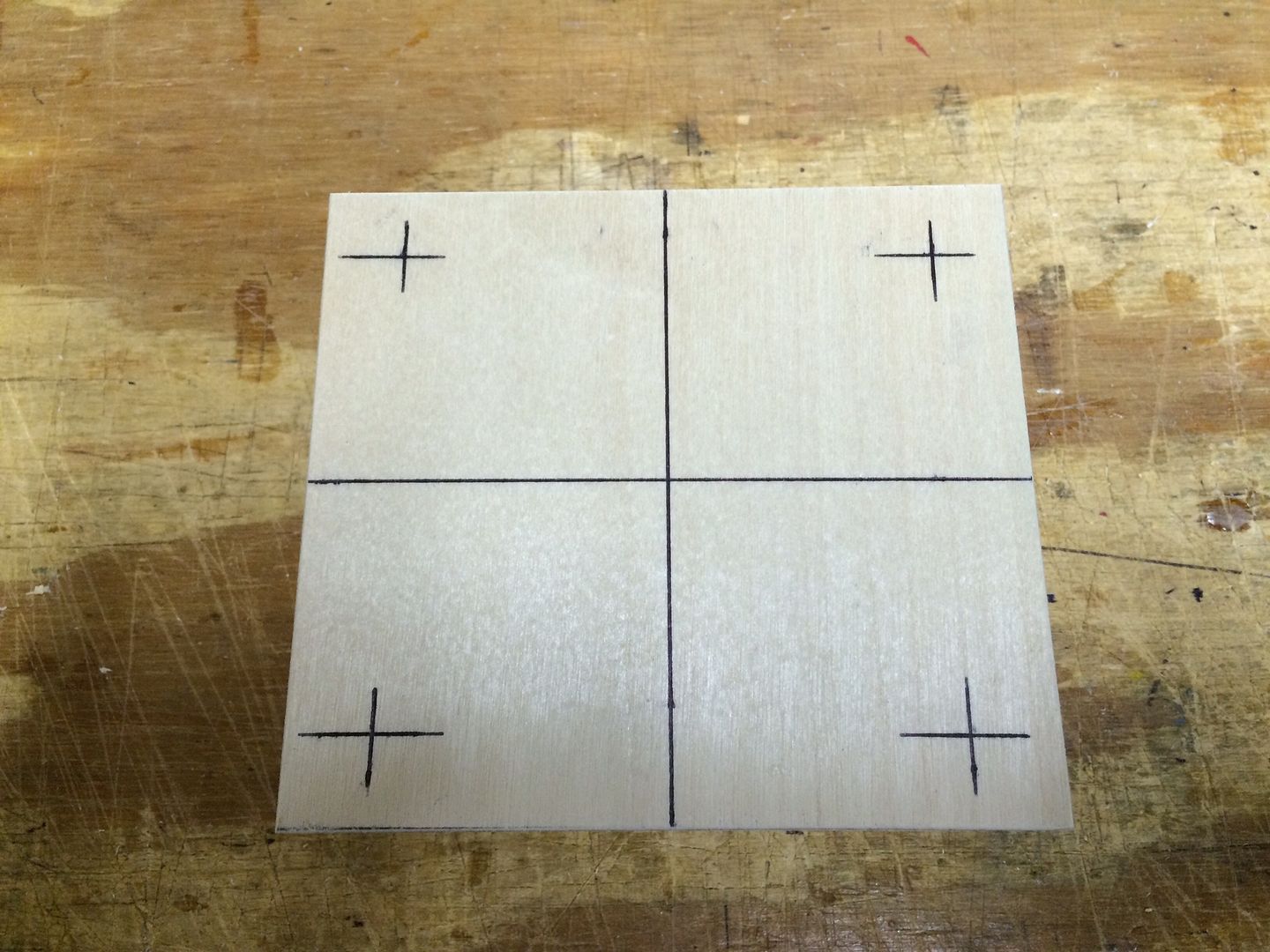

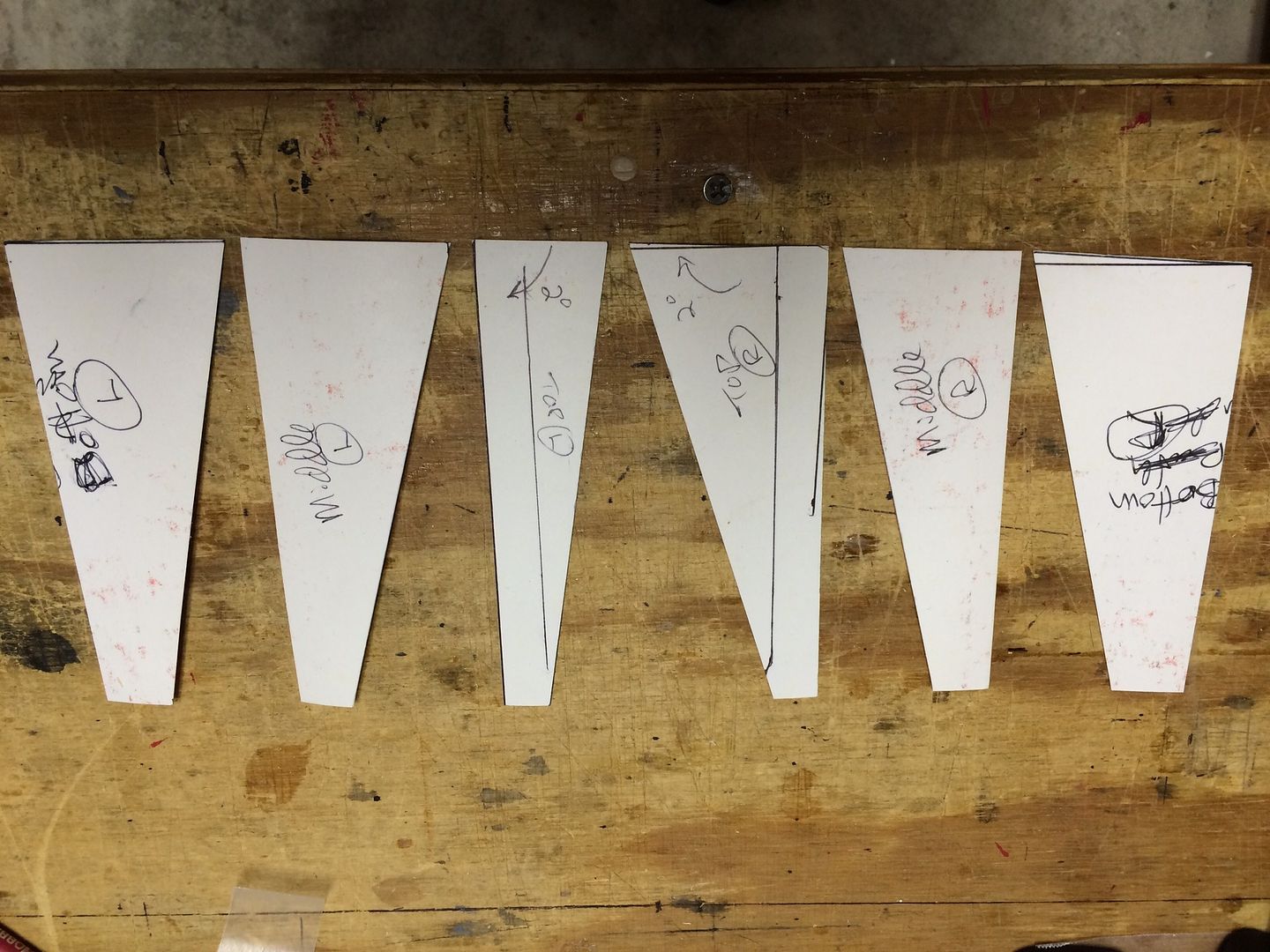

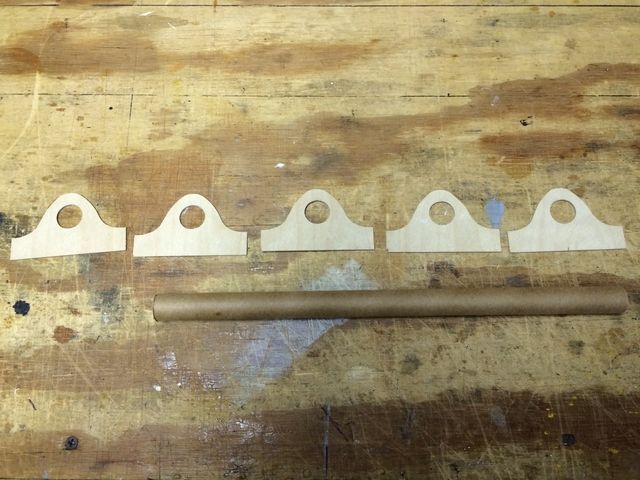

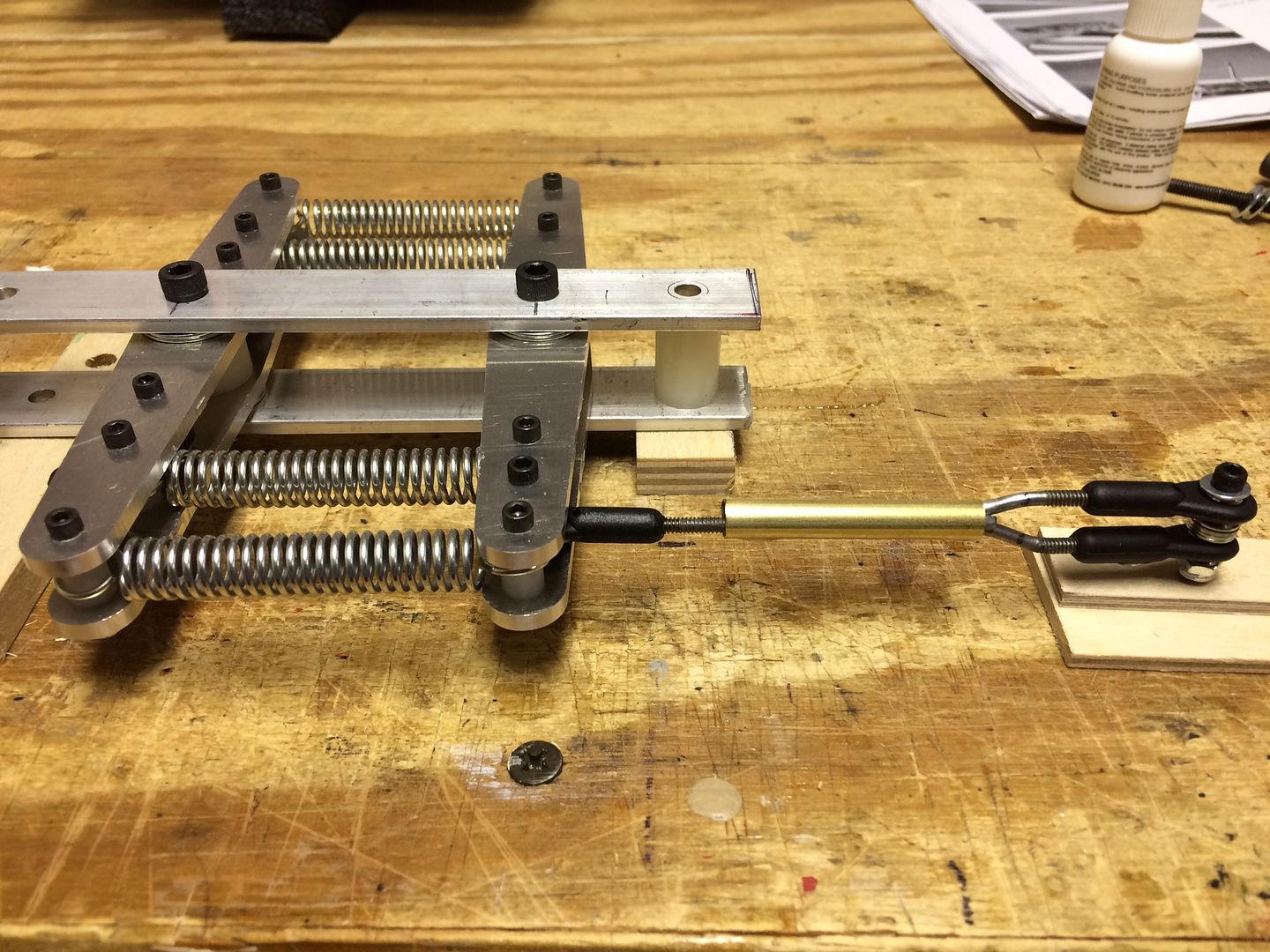

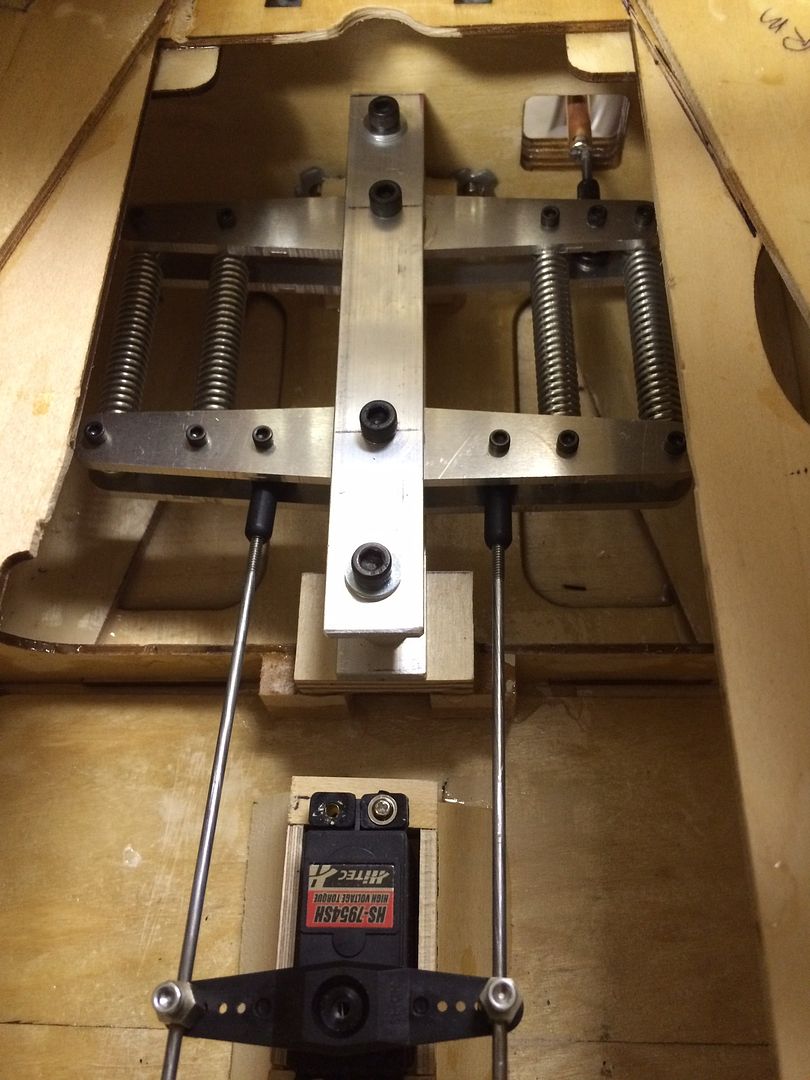

First is mounting the engine. We have opted for a DA-170 engine to power our Bidule. The engine needs to be spaced 1-5/8" out from the main firewall and we elected to build a plywood box spacer. This method has worked very well for us on numerous other models, so we are sticking with what we know. Here are our un assembled parts.

The box is 4-1/4" wide and 4-5/8" tall.

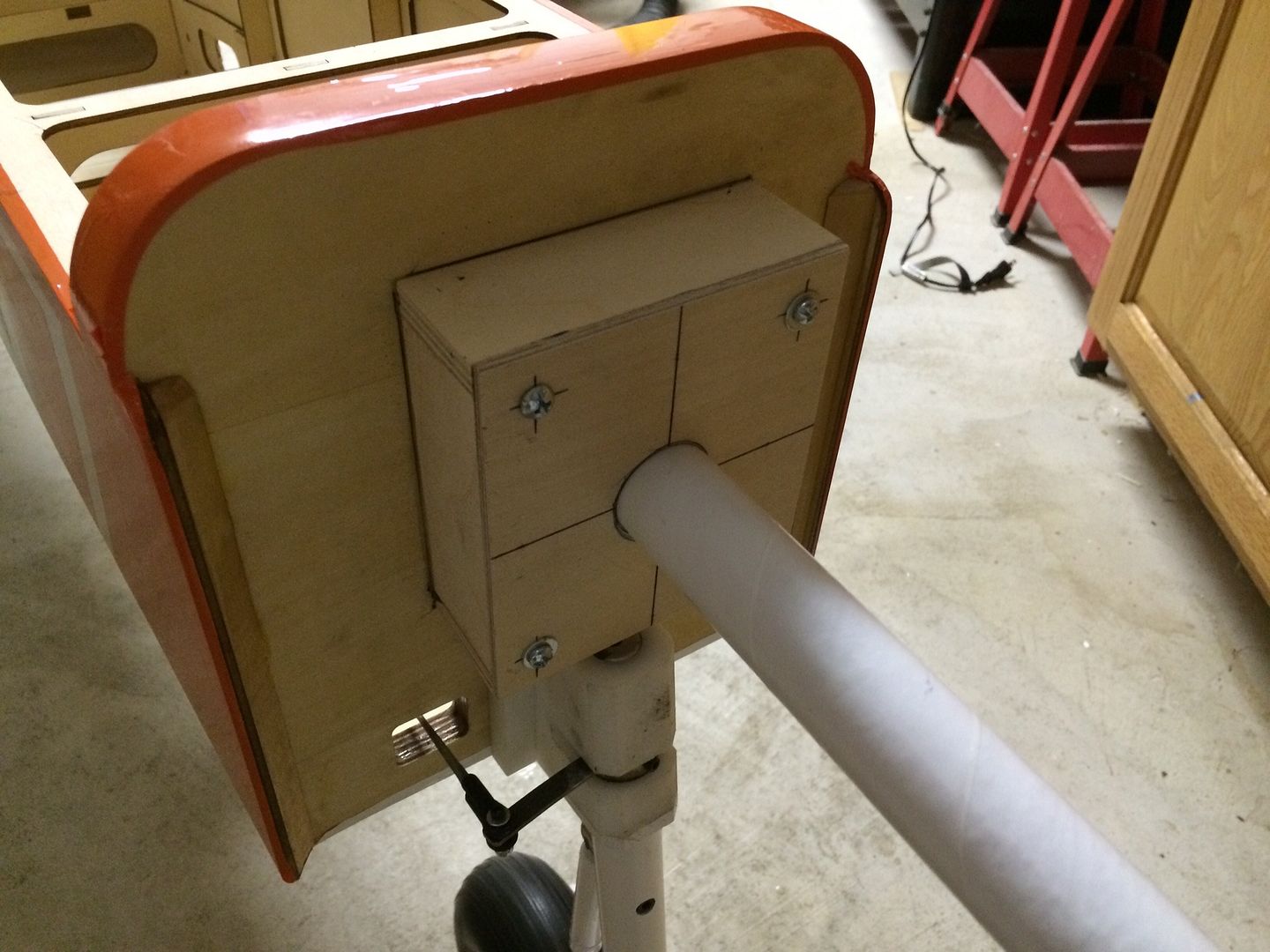

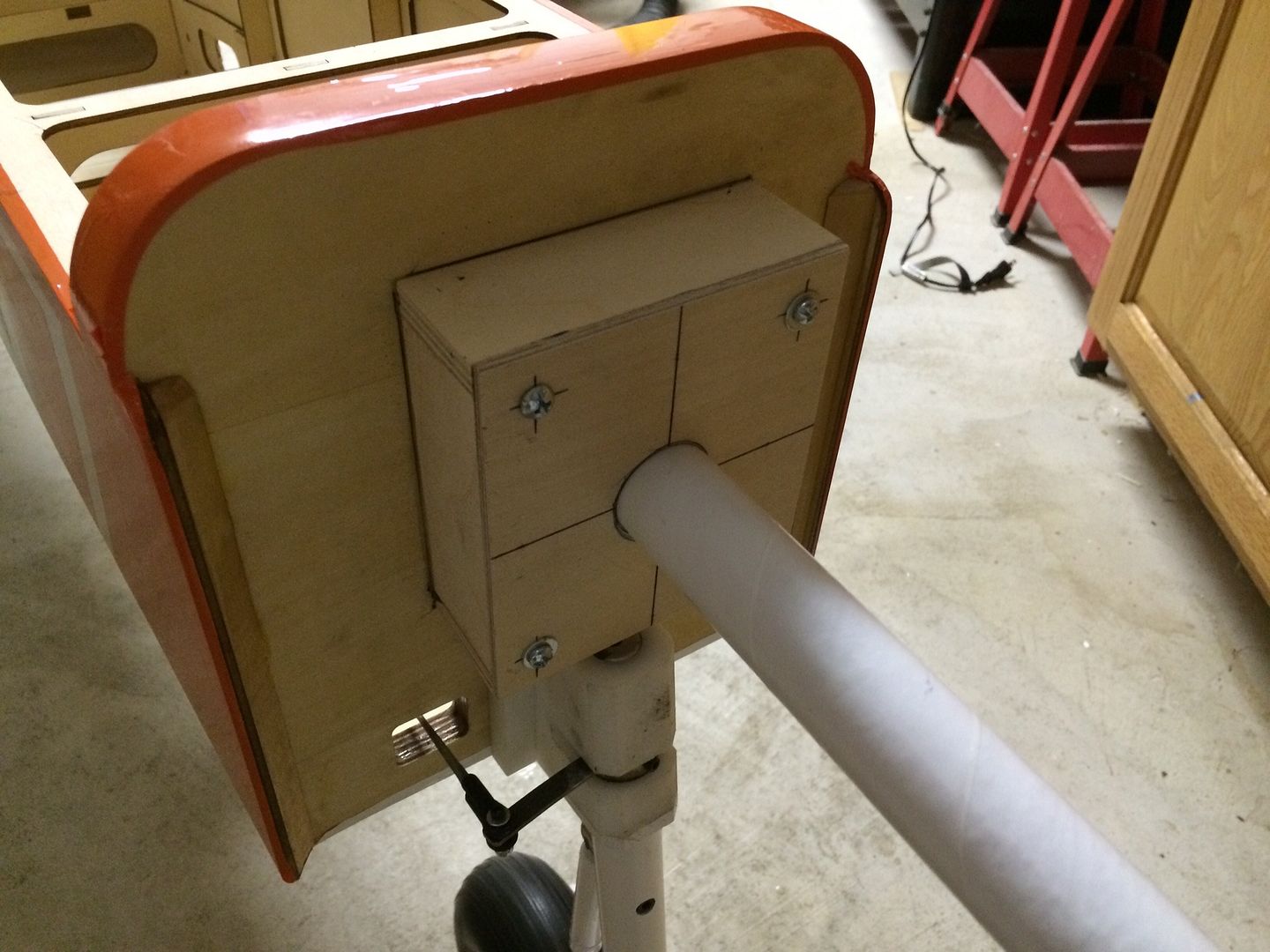

The sides were cut to 1-1/2" wide with the firewall inset inside these side pieces.

A second layer of 1/8" plywood was added to the front of the box.

We cut a center hole the same diameter as the one in the main firewall and inserted a cardboard tube that the ignition wires will pass through. The engine mounting bolt holes were used to secure the box to the main firewall while the epoxy cures.

Bob has already posted extensive pictures of his build and modifications, but I am taking a little different path than either he or Len. This plane will no doubt be the subject of numerous build threads and every builder has their own ideas. This will be my take on the subject.

First is mounting the engine. We have opted for a DA-170 engine to power our Bidule. The engine needs to be spaced 1-5/8" out from the main firewall and we elected to build a plywood box spacer. This method has worked very well for us on numerous other models, so we are sticking with what we know. Here are our un assembled parts.

The box is 4-1/4" wide and 4-5/8" tall.

The sides were cut to 1-1/2" wide with the firewall inset inside these side pieces.

A second layer of 1/8" plywood was added to the front of the box.

We cut a center hole the same diameter as the one in the main firewall and inserted a cardboard tube that the ignition wires will pass through. The engine mounting bolt holes were used to secure the box to the main firewall while the epoxy cures.

Comment