In the fall of 2021 I learned that Rosenthal Models USA https://rosenthalmodelsusa.comhad a 6m Choco Fly SB 14 on order that was not spoken for, so I put my name on it. More information about the full-scale SB 14 can be found here (use google translate for both pages).

And also a link to the Choco Fly website. Scroll down to find the 6m SB 14.

My glider was ordered with the canopy installed with latch, complete seat tray, Ceflix retract installed, tailwheel installed, instrument pod and detailed instrument panel, wing and fuselage bags and red trim.

The SB 14 is a GPS racer so there is a lot of carbon in the wings and fuse. The wings are beautifully molded and are of top quality. Each side of the wing has one flap and two ailerons. There are no spoilers in order to keep the airfoil as clean as possible, and the flaps are large enough to ensure good glide path control using crow/butterfly. The fuse is carbon from the back of the canopy to the tail. There is some Kevlar in the nose and in the wing/landing gear area. Also very nicely molded. The insides of all the components are clean and neat, much like the inside of a premium acoustic guitar.

I'm going to install a Torcman FES system in the nose fed by a yet-to-be-determined ESC and use ChocoMotion Fox servos. The ChocoMotion servos, generally speaking, cost a bit more than KST and are a bit less than MKS servos. In some sizes they are more powerful than the other brands, and some are the same size and can be used as replacements for KST or MKS. As all of these components are installed I will describe each specific item in more detail. Fortunately, Rosenthal Models USA (aka Bruce DeVisser) carries Torcman FES systems and Fox servos, plus all the accessories needed to get this bird in the air. Things like cockpit details, aerotow releases, fuselage side mounts for servos, battery boxes, LDS/IDS servo drives, and a beautiful and very scale removable Prandtl probe for pitot/static. In addition to carrying models from Choco Fly, he is also a dealer for Tomahawk Aviation, Rosenthal Models, Florian Shambeck, LeoMotion motors and Torcman e-machines.

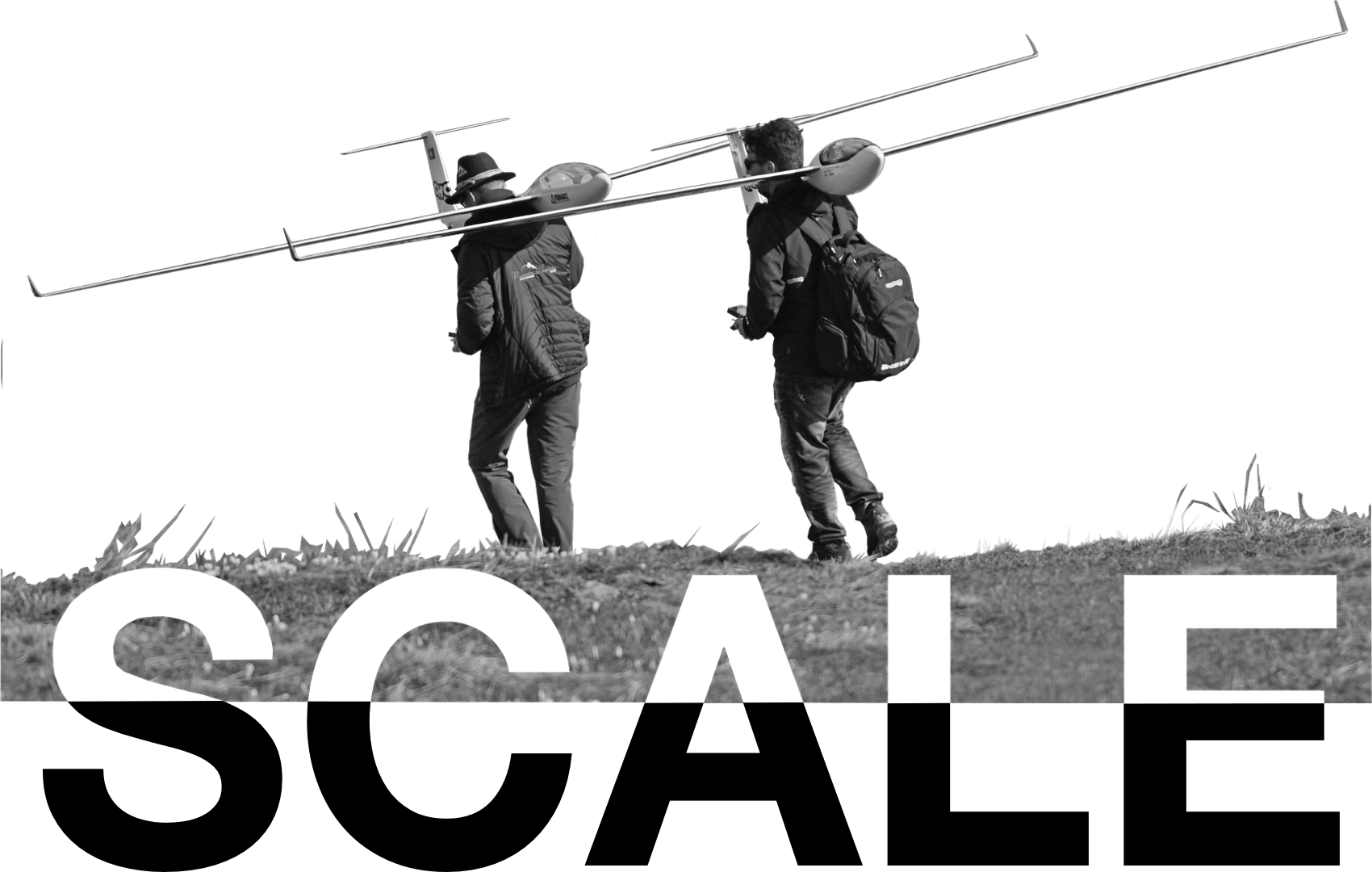

After unpacking and finding everything present and with no signs of damage, it is time to put it together! Surprisingly, everything fit together! The airframe weighs 18 lbs so it will probably be a good floater. There are ballast tubes in each wing so it can also be loaded up.

I use Jeti avionics and will use a CB 220 for power management and short protection, two REX 12 receivers for primary and backup RX, a R3/RSW receiver switch to turn the plane on and off using the transmitter, a Mvario 2 and a Mspeed EX airspeed sensor.

Here we go...

And also a link to the Choco Fly website. Scroll down to find the 6m SB 14.

My glider was ordered with the canopy installed with latch, complete seat tray, Ceflix retract installed, tailwheel installed, instrument pod and detailed instrument panel, wing and fuselage bags and red trim.

The SB 14 is a GPS racer so there is a lot of carbon in the wings and fuse. The wings are beautifully molded and are of top quality. Each side of the wing has one flap and two ailerons. There are no spoilers in order to keep the airfoil as clean as possible, and the flaps are large enough to ensure good glide path control using crow/butterfly. The fuse is carbon from the back of the canopy to the tail. There is some Kevlar in the nose and in the wing/landing gear area. Also very nicely molded. The insides of all the components are clean and neat, much like the inside of a premium acoustic guitar.

I'm going to install a Torcman FES system in the nose fed by a yet-to-be-determined ESC and use ChocoMotion Fox servos. The ChocoMotion servos, generally speaking, cost a bit more than KST and are a bit less than MKS servos. In some sizes they are more powerful than the other brands, and some are the same size and can be used as replacements for KST or MKS. As all of these components are installed I will describe each specific item in more detail. Fortunately, Rosenthal Models USA (aka Bruce DeVisser) carries Torcman FES systems and Fox servos, plus all the accessories needed to get this bird in the air. Things like cockpit details, aerotow releases, fuselage side mounts for servos, battery boxes, LDS/IDS servo drives, and a beautiful and very scale removable Prandtl probe for pitot/static. In addition to carrying models from Choco Fly, he is also a dealer for Tomahawk Aviation, Rosenthal Models, Florian Shambeck, LeoMotion motors and Torcman e-machines.

After unpacking and finding everything present and with no signs of damage, it is time to put it together! Surprisingly, everything fit together! The airframe weighs 18 lbs so it will probably be a good floater. There are ballast tubes in each wing so it can also be loaded up.

I use Jeti avionics and will use a CB 220 for power management and short protection, two REX 12 receivers for primary and backup RX, a R3/RSW receiver switch to turn the plane on and off using the transmitter, a Mvario 2 and a Mspeed EX airspeed sensor.

Here we go...

Comment