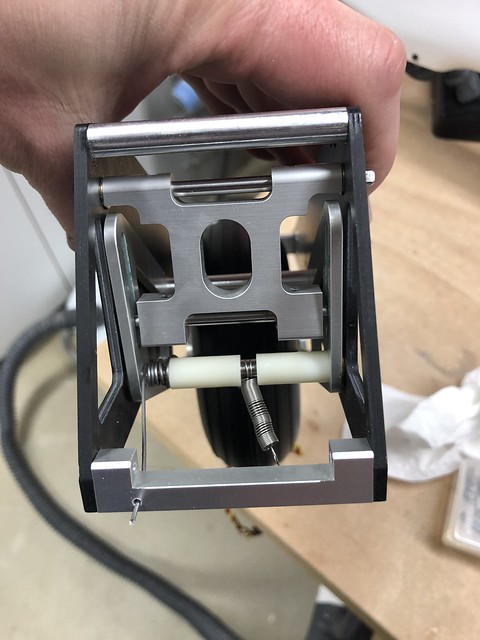

Finished fabricating my new CG machine so I got a chance to try it out on the ASH31. Worked like I had hope and was very stable.

Straight sailplane (no motor), fully flight configured it needed 34.4oz (2.15lbs.) to get it to balance right in the middle of the published CG range.

Straight sailplane (no motor), fully flight configured it needed 34.4oz (2.15lbs.) to get it to balance right in the middle of the published CG range.

Comment