My tremendous flying skills exhibited at this year's Horizon Aerotow left me in need of a replacement canopy for a 4.2m Discus 2b. The take away... always keep your finger on the tow release switch when taking off.

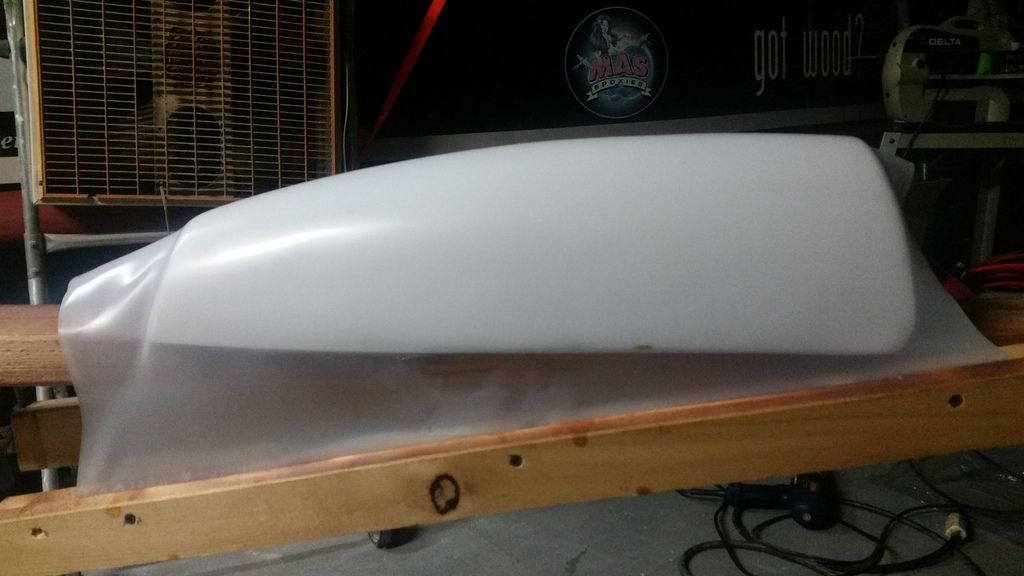

The plug is carved from blue/pink foam. I got it close to final shape and then sanded the last bit down while it was in place on the fuselage. The pink sections were added so the pulled canopy can be trimmed to size.

Next step will be to cover it with two layers of 1.2 oz cloth then some bondo before sanding it smooth. The resulting plug will be used to pull some clear canopies.

I read about one gentleman who used paper mache and wood filler for these steps under a coat of primer. I may have to give that a try in the future. I'm sure there will be a need for other canopies.

He also mentioned wiping a little cooking oil on the plug before pulling the plastic canopy. The reduced friction provided an easier pull and more consistent thickness.

The plug is carved from blue/pink foam. I got it close to final shape and then sanded the last bit down while it was in place on the fuselage. The pink sections were added so the pulled canopy can be trimmed to size.

Next step will be to cover it with two layers of 1.2 oz cloth then some bondo before sanding it smooth. The resulting plug will be used to pull some clear canopies.

I read about one gentleman who used paper mache and wood filler for these steps under a coat of primer. I may have to give that a try in the future. I'm sure there will be a need for other canopies.

He also mentioned wiping a little cooking oil on the plug before pulling the plastic canopy. The reduced friction provided an easier pull and more consistent thickness.

Comment